Commercial Offices

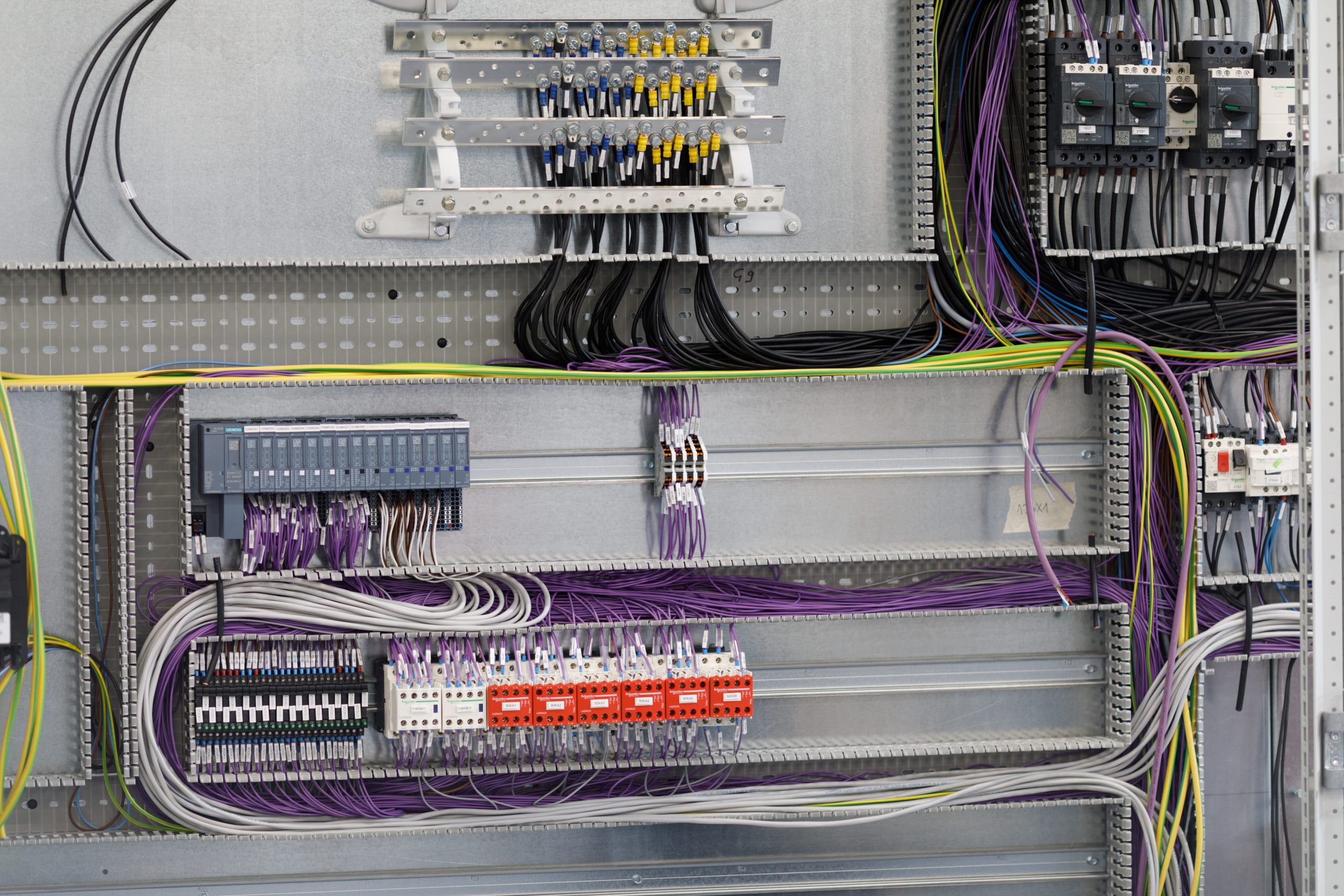

Applications: Lighting & small power, distribution boards & risers, UPS/essential power, emergency lighting, BMS/HVAC control, lifts/escalators plant rooms, ELV control power (FA/Access/CCTV).

Cable families: Domestic wires 300/500V & 450/750V, LV power 0.6/1 kV (2–4 core), Control 300/500V (unshielded/shielded).

Standards: IEC / BS / UL

Why it matters: Uniform color coding & clear legends speed installation and reduce rework

Service: Typical lead time 2–4 weeks • Export-ready packing • Routine test reports supplied

Cables for this sector

Domestic Wires (300/500V, 450/750V) — Solid/stranded copper with PVC insulation for lighting, sockets, and panel wiring; standard office color sets; LSZH optional.

LV Power Cables (0.6/1 kV, 2–4 core) — CU/PVC/PVC unarmoured for mains, sub-mains, and UPS/essential circuits; reduced neutral option on request.

Control Cables (300/500V) — Unshielded or foil/braid shielded for BMS, HVAC, and access control; numbered or color-coded cores.

Why our cables are vital in commercial offices

Compliance & safety — Built to IEC/BS/UL; routine test reports included for quick consultant approvals.

Speed & neatness — Consistent colors/legends and numbered cores minimize errors and rework during fast-track fit-outs.

Program friendly — 2–4 week typical lead times, pre-cut lengths, and floor-by-floor deliveries keep phases moving.

Traceability — Batch numbers and labeling make maintenance and warranty straightforward.

Why Golden Hills Co Produts

Sector Overview

Office projects move fast—tight programs, phased floors, and strict safety standards. Golden Hills Co manufactures the domestic wires, LV power cables, and control cables that office contractors rely on for lighting, small power, panel feeders, risers, UPS/essential circuits, and BMS/HVAC.

We build to IEC/BS/UL requirements and verify every batch with in-house testing. Consistent color coding, crisp print legends, and numbered cores keep installation clean and inspection quick. For occupied buildings or multi-floor fit-outs, we can pre-cut lengths, provide floor-by-floor call-offs, and label drums clearly to match your drawings and schedules.

Implementation process

BOQ & Specification Review — Map standards, color codes, conductor classes, and any LSZH needs to the project spec.

Value & Alternates — Where allowed, propose compliant alternates and reel lengths to reduce waste and time on site.

Samples & Approvals — Provide color samples, print legends, and routine test formats for consultant sign-off.

Manufacture & Test — Controlled production with routine tests (resistance, insulation, spark/voltage) and batch traceability.

Pack & Deliver — Floor-labeled reels, packing lists, HS codes, and test reports; deliveries sequenced to your program.

View more

Industries We Serve