Utilities & Street Lighting

Applications: Lighting circuits, sockets & small power, panel feeders, risers, BMS/HVAC control

Cable families: Domestic wires (300/500V, 450/750V) • LV power (0.6/1 kV, 2–4 core) • Control (300/500V)

Standards: IEC / BS / UL

Why it matters: Uniform color coding & clear legends speed installation and reduce rework

Service: Typical lead time 2–4 weeks • Export-ready packing • Routine test reports supplied

Cables for this sector

Domestic Wires (300/500V, 450/750V) — Solid/stranded copper with PVC insulation for lighting, sockets, and panel wiring; standard market color sets.

LV Power Cables (0.6/1 kV, 2–4 core) — CU/PVC/PVC unarmoured for mains & sub-mains; reduced neutral option available.

Control Cables (300/500V) — Unshielded or foil/braid shielded for BMS, HVAC, and access control; numbered or color-coded cores.

Why our cables are vital for utilities & street lighting

Public safety & compliance — Built to IEC/BS/UL with routine test reports for authority approvals.

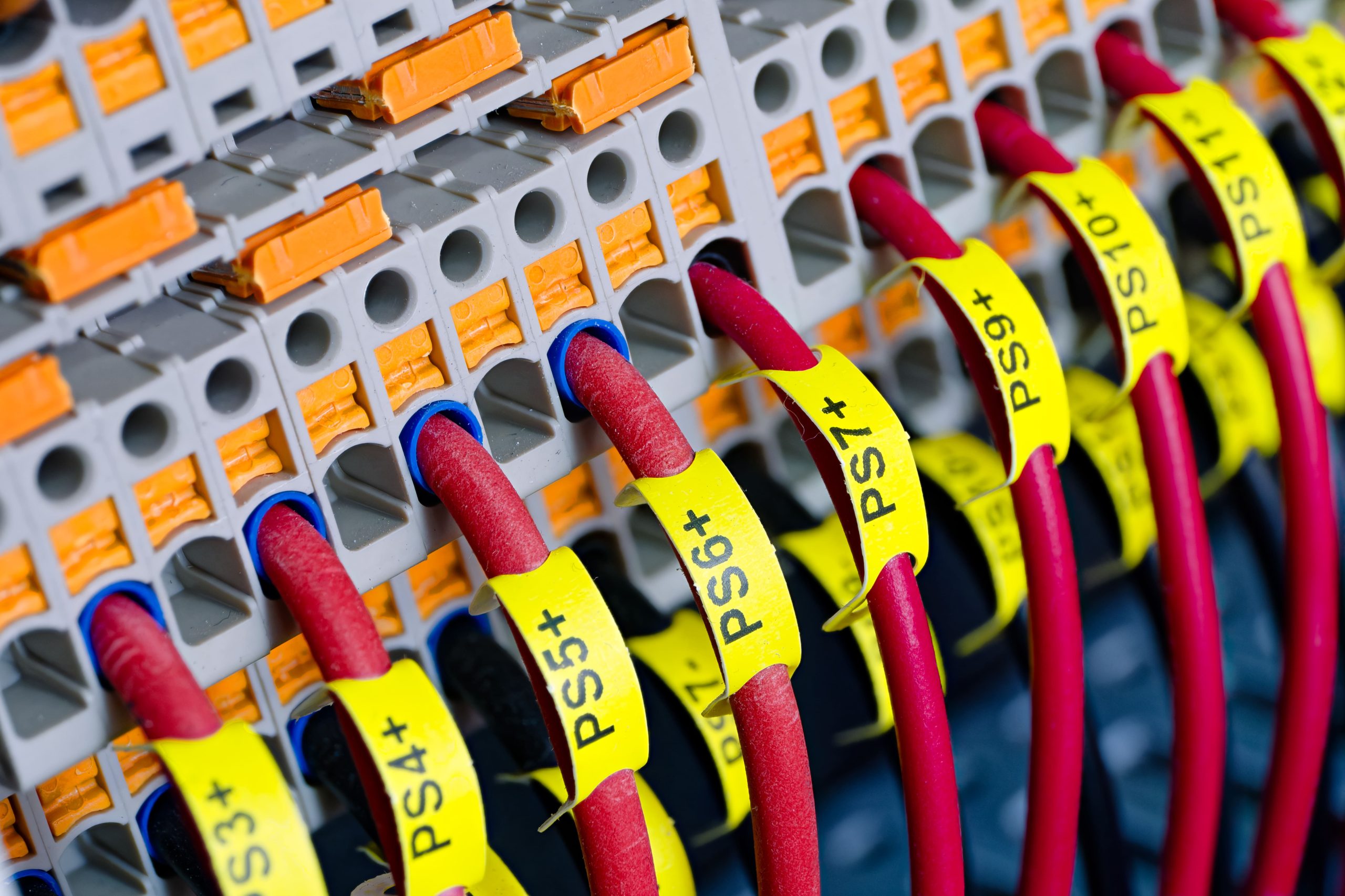

Speed at night — Consistent colors/legends and pre-cut, zone-labeled reels reduce on-site time and reopen roads sooner.

Maintenance made easier — Numbered cores and clear labeling support fast troubleshooting and planned shutdowns.

Program certainty — 2–4 week typical lead times and sequenced deliveries keep works aligned with traffic management.

Why Golden Hills Co Produts

Sector Overview

Public-realm projects run to tight night windows and strict safety standards. Golden Hills Co supplies domestic wires, LV power cables, and control cables for feeder pillars, lighting columns, parks & walkways, tunnels/underpasses, and control systems (photocells, timers, CMS).

We build to IEC/BS/UL requirements and batch-test in-house. Consistent color coding and crisp print legends speed termination and inspection, while numbered cores and clear drum labels help maintenance teams fault-find quickly. When specs call for it, we can provide LSZH for enclosed areas and armoured/XLPE variants on request. Deliveries can be pre-cut and labeled by zone/circuit to align with night works and traffic plans.

Implementation process

BOQ & Code Review — We check your BOQ, match standards, and align color codes and legends with project specs.

Spec Matching & Alternates — We confirm conductor class, voltage rating, and construction; provide compliant alternates if needed.

Samples & Approvals — Color samples and print legends available for consultant/owner sign-off.

Manufacture & Test — Controlled production with routine tests (resistance, insulation, spark/voltage) and batch traceability.

Pack & Deliver — Export-ready packing, documents, and clear drum/reel labeling for site logistics.

Outcome: Faster approvals, fewer site surprises, and cables that install the way drawings intend.

View more

Industries We Serve