Residential & Housing

Applications: Lighting circuits, sockets & small power, panel feeders, risers, BMS/HVAC control

Cable families: Domestic wires (300/500V, 450/750V) • LV power (0.6/1 kV, 2–4 core) • Control (300/500V)

Standards: IEC / BS / UL

Why it matters: Uniform color coding & clear legends speed installation and reduce rework

Service: Typical lead time 2–4 weeks • Export-ready packing • Routine test reports supplied

Cables for this sector

Domestic Wires (300/500V, 450/750V) — Solid/stranded copper with PVC insulation for lighting, sockets, and panel wiring; standard market color sets.

LV Power Cables (0.6/1 kV, 2–4 core) — CU/PVC/PVC unarmoured for mains & sub-mains; reduced neutral option available.

Control Cables (300/500V) — Unshielded or foil/braid shielded for BMS, HVAC, and access control; numbered or color-coded cores.

Why our cables are vital in residential work

Safety & compliance — Built to IEC/BS/UL with routine test reports for consultant approval.

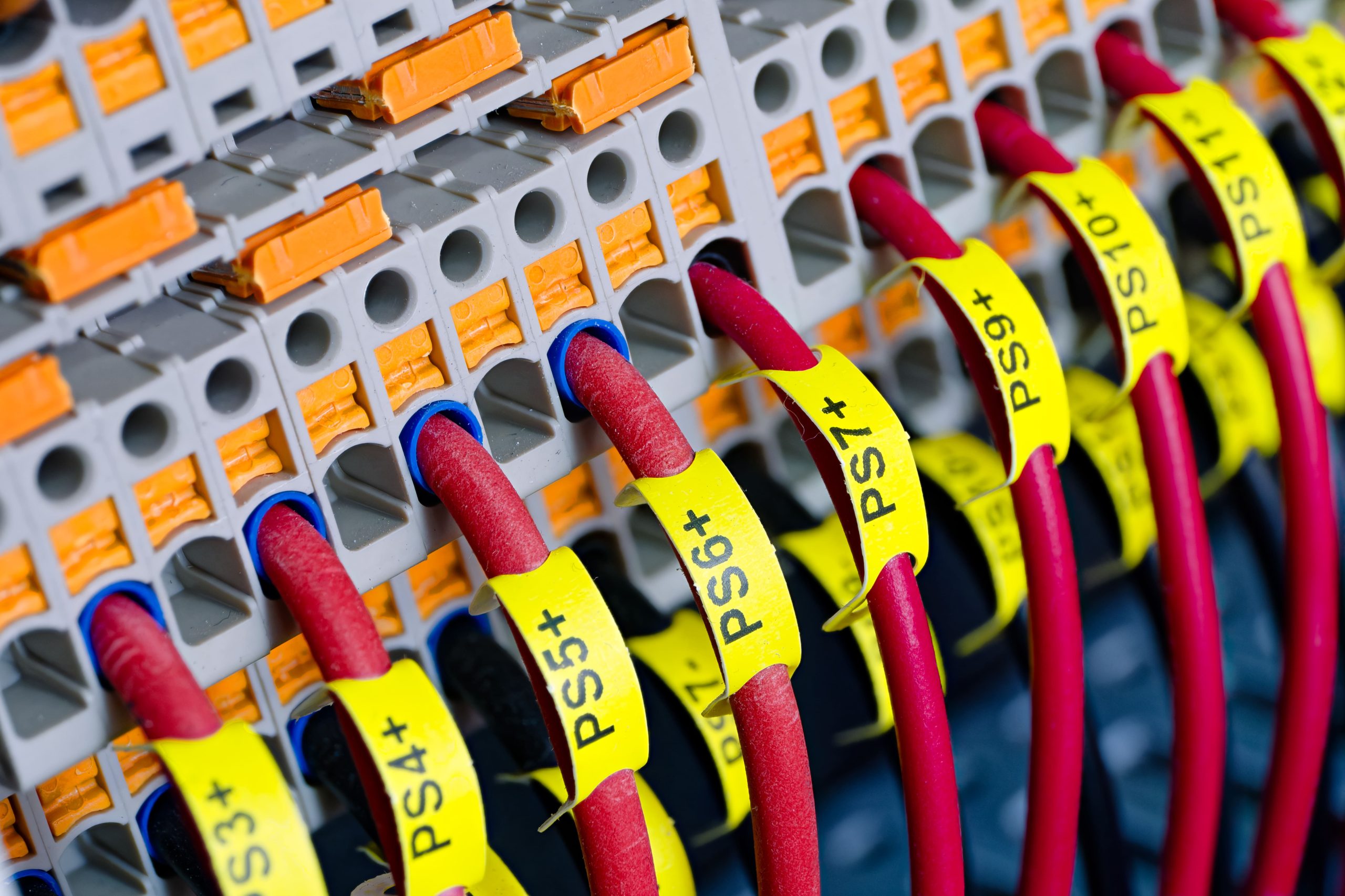

Speed on site — Consistent color coding and crisp print legends reduce errors and rework.

Reliable delivery — 2–4 week typical lead times for standard items; cut-to-length available.

Traceability — Batch numbers and labeling make maintenance and warranty straightforward.

Why Golden Hills Co Produts

Sector Overview

Residential projects demand wiring that is safe, consistent, and easy for installers to work with. Golden Hills Co manufactures domestic wires, low-voltage power cables, and control cables to IEC/BS/UL requirements, with in-house testing on every batch. Uniform color coding and crisp print legends make identification simple in panels and conduits, while realistic lead times keep fit-outs and handovers on schedule.

Whether you’re wiring villas, apartment towers, or mixed-use developments, our cables cover everything from lighting and sockets to main feeders, risers, and BMS/HVAC control. We provide datasheets and routine test reports with orders so approvals move quickly.

Implementation process

BOQ & Code Review — We check your BOQ, match standards, and align color codes and legends with project specs.

Spec Matching & Alternates — We confirm conductor class, voltage rating, and construction; provide compliant alternates if needed.

Samples & Approvals — Color samples and print legends available for consultant/owner sign-off.

Manufacture & Test — Controlled production with routine tests (resistance, insulation, spark/voltage) and batch traceability.

Pack & Deliver — Export-ready packing, documents, and clear drum/reel labeling for site logistics.

Outcome: Faster approvals, fewer site surprises, and cables that install the way drawings intend.

View more

Industries We Serve